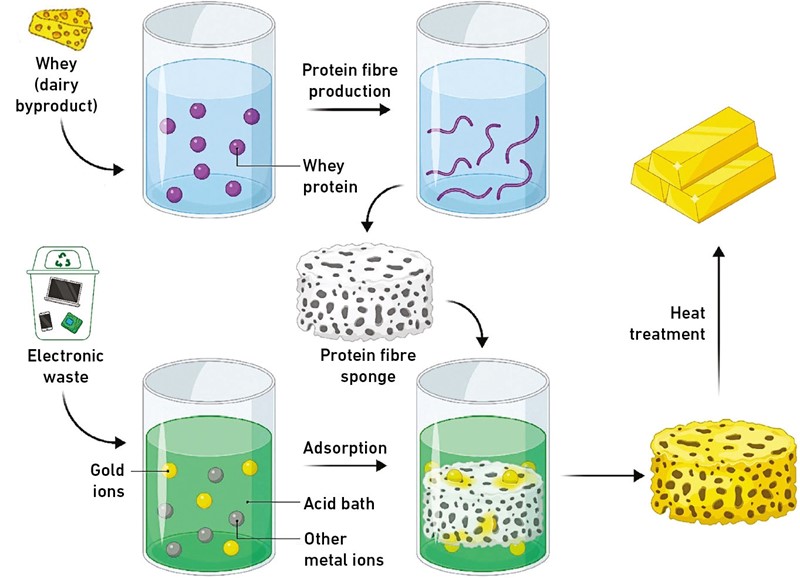

After dissolving the metal parts of 20 motherboards in an acidic bath, a nugget of 22-karat gold weighing 0.45 grams was obtained.

Alchemists have always sought to turn ordinary, less valuable materials into gold. It seems that something similar has now succeeded with scientists from the Swiss Federal Institute of Technology ETH in Zurich; they extracted gold from electronic waste using a byproduct of the cheese production process. This method was presented in the journal Advanced Materials.

Briefly, they dissolved the metal parts of 20 old motherboards in an acidic bath to ionize the metals. And when they immersed a sponge made from denatured whey proteins into the solution, gold ions adhered to the protein fibers. By heating the sponge, the gold ions were converted into flakes, which the scientists then melted into gold. Thus, from 20 motherboards, they obtained a grain of 0.45 grams consisting of 91 percent gold, equivalent to 22 karats, with the remainder being copper.

This process, they say, is commercially viable because the material and energy costs are 50 times lower than the value of the obtained gold. Researchers aim to repeat the principle with waste from microchip production and gold plating processes and see if protein fibril sponges can be made from other protein-rich byproducts or waste from the food industry.

CHATGPT4 DESIGNS BRAIN-INSPIRED CHIPS

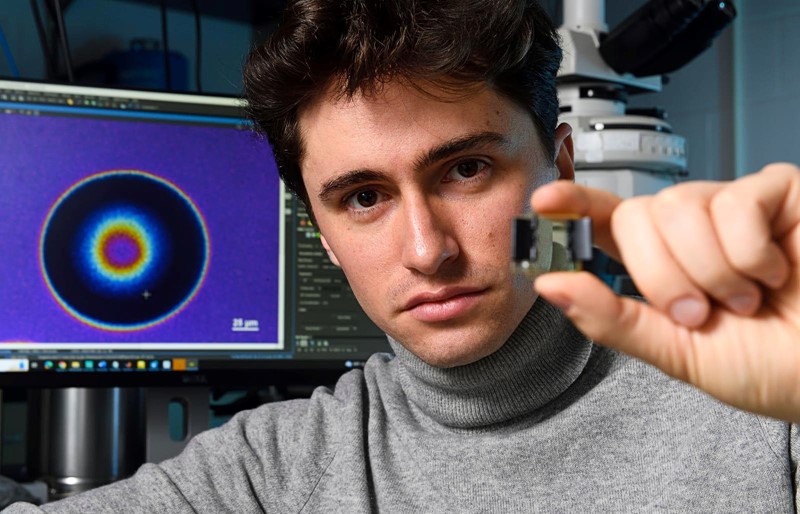

Electrical and computer engineers from the Andreou Lab pioneered a new approach to creating neuromorphic accelerators that could power energy-efficient artificial intelligence in autonomous vehicles and robots. They devised a way to create a neural network chip with spikes, similar to the human brain, using natural language instructions and ChatGPT4.

The chip’s network architecture consists of a small silicon brain with two layers of interconnected neurons. Users can adjust the strength of these connections using an 8-bit addressable system. Reconfiguration and programming capabilities are achieved using a user interface, a subsystem of the standard Serial Peripheral Interface (SPI) also designed by ChatGPT, using natural language instructions. The chip is then “printed” at the Skywater chip fabrication service in an inexpensive 130-nanometer CMOS process.

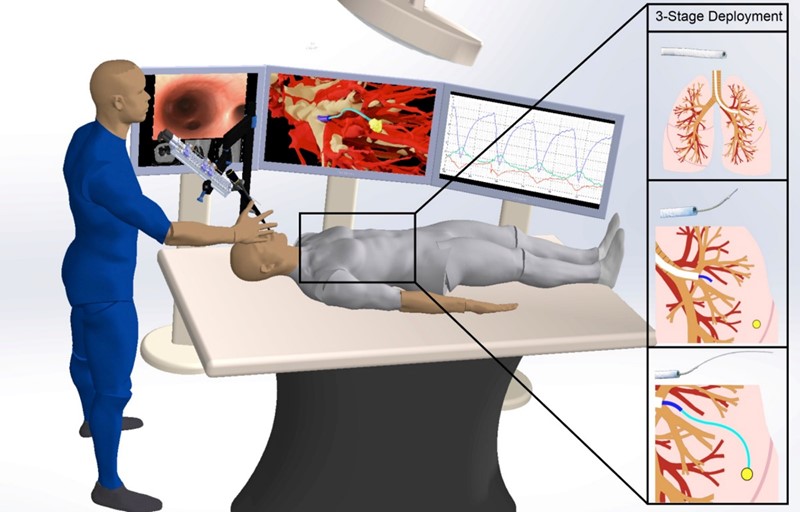

SELF-GUIDED NEEDLE FOR SAFER BIOPSY

Lungs pose a significant challenge for physicians and treatment due to their dense network of blood vessels, bronchi, and other anatomical structures, making it difficult to reach distant lung nodules with conventional bronchoscopy. However, researchers from the University of North Carolina at Chapel Hill, Vanderbilt University, and the University of Utah have developed a compact robotic system capable of autonomously maneuvering a flexible needle around these anatomical obstacles within the lungs.

A three-stage arrangement of the semi-autonomous robot in the lungs: the doctor manually controls the bronchoscope through the airways (top); the doctor remotely controls the aiming device (middle); and autonomously inserting the needle through tissue to the nodule (bottom).

It is the first robot capable of simultaneously autonomously guiding a needle, performing in vivo work, and avoiding anatomical obstacles. The system includes autonomous navigation control for precise needle movement through the lungs, reducing the possibility of human error and ensuring better outcomes for medical procedures, say scientists in a preclinical study published in Science Robotics.

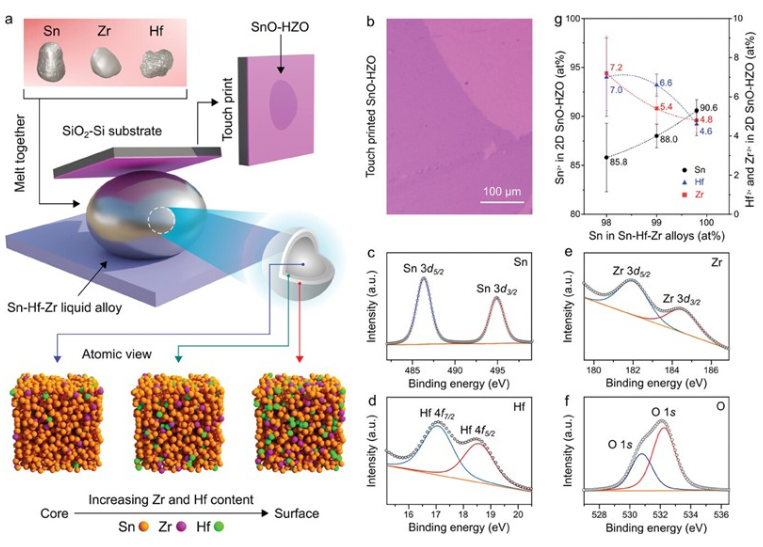

NANOTANKS PRINTING ELECTRONIC HARDWARE

Engineers at the University of Sydney have developed a 2D printing process using liquid metals. This process, described in the journal Small, could enable new ways of creating more advanced and energy-efficient computer hardware produced on the nanoscale.

Combining tin, zirconium, and hafnium in precise proportions enabled the alloy to melt at temperatures below 500 degrees Celsius, far lower than the individual melting points of zirconium (1855 degrees) and hafnium (2227 degrees). The liquid metal alloy has a thin oxide layer or “skin” and a liquid center, used to collect ultrathin nanoplates of hafnium-doped tin oxide.

“These sheets form the basis of the next generation of computer hardware, from semiconductors to memory chips,” claim Australian researchers. “This process allows us to introduce ferroelectricity into much smaller, 2D metal oxides, enabling the development of the next generation of nanoelectronics at low temperatures.”

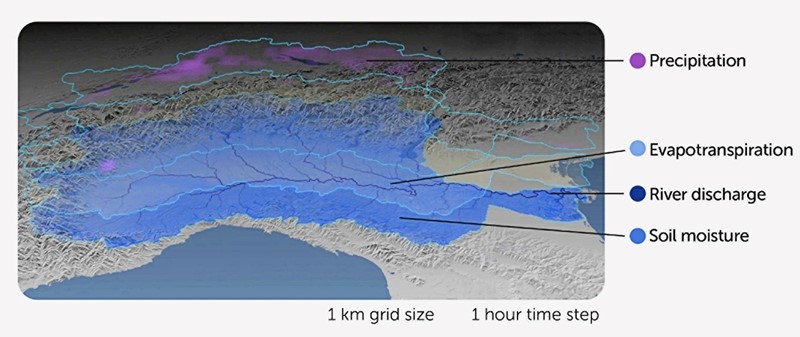

DIGITAL EARTH TWIN FOR DISASTER PREDICTION

The scientific journal Frontiers in Science has introduced a new digital hydrological platform of Earth’s twin that could help us predict water-related natural disasters. This most detailed platform to date combines new high-resolution satellite observations and cutting-edge modeling to create a test environment that matches our planet.

Researchers from the Italian National Research Council used vast amounts of data on soil moisture, precipitation, evaporation, river flow, and snow height, collected every hour per observed kilometer. The resulting model was incorporated into a cloud-based platform to allow researchers to map flood and landslide risks and manage water resources.

The project began by modeling the Po River valley, and the digital twin was then expanded to other parts of the Mediterranean basin. The researchers plan to extend the principle to the entire Europe, and later to the whole world.

DIESEL ENGINE ON VEGETABLE OIL

Engineers from the Russian University of Peoples’ Friendship (RUDN) studied how the performance of internal combustion engines changes by adding rapeseed oil instead of diesel fuel. These data, presented on the E3S Web, should help regulate engine operation and potential transition to plant-based biofuel.

RUDN engineers experimented on a small high-speed diesel engine type MD-6 used in small agricultural machinery. Using rapeseed oil increased the maximum fuel injection pressure and fuel delivery duration, but to make the diesel engine work on rapeseed oil, it is necessary to reconfigure the fuel delivery parameters, injection and atomization settings, and change the dimensions of the combustion chamber. Engineers claim to have also discovered how to best adapt the engine, which they will report on in future work.

NEW ‘WATER BATTERIES’, CHEAPER AND SAFER

So-called water batteries, or water-based metal-ion batteries, use less toxic metals such as magnesium or zinc, and instead of sulfuric acid or lithium salts, the electrolytic fluid is water with a few added salts. Researchers at the University of Melbourne (RMIT) have devised a way to recycle such a battery and, more importantly, prevent the short circuit that occurs when tiny needle-like metal protrusions, dendrites, form on the metal anode inside the battery.

Researchers coated the zinc battery anode with bismuth metal, which oxidizes and forms rust, but also a protective layer that prevents dendrite formation. This also extends the life of the water battery, which retains over 85 percent of its capacity even after 500 cycles, experiments described in the journal Advanced Materials have shown.

Australians have so far developed prototypes of coin-sized batteries used in watches and cylindrical ones resembling traditional AA or AAA batteries, and now they want to improve their energy density to be comparable to small lithium-ion batteries for pocket-sized devices. They prefer magnesium as the material because it is lighter than zinc and has higher potential energy density. If successful, magnesium-ion batteries could replace bulky lead-acid batteries within a few years.

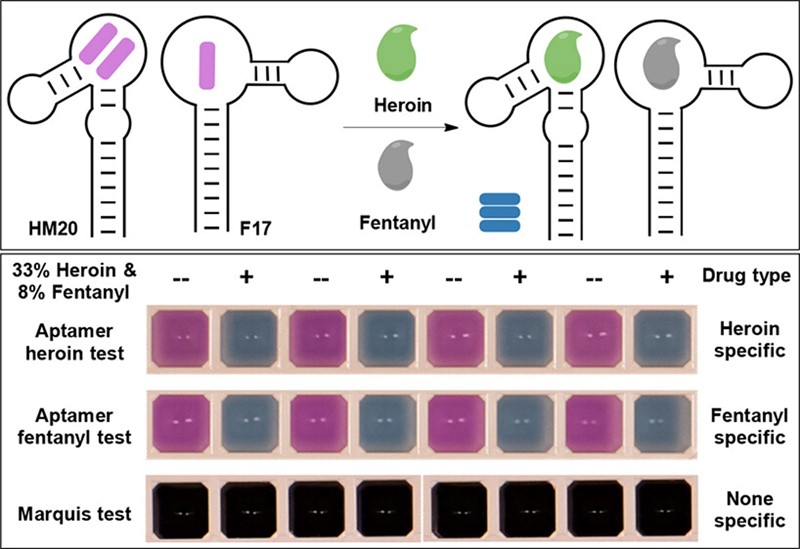

COCAINE, HEROIN, AND FENTANYL DETECTOR

Researchers at North Carolina State University have developed a new generation of highly efficient DNA aptamers and highly accurate sensors for detecting opioids. The sensors, described in two studies in the journals of the American Chemical Society (JACS) and JACS Au, can detect traces of fentanyl, heroin, and cocaine, even when mixed with other drugs, caffeine, sugar, or procaine.

Researchers at the University of California, Santa Barbara, have successfully integrated an aptamer into an electrode that measures the concentration of drugs in a rat’s vein. NCSU.

The aptamer is a short single-stranded DNA or RNA chain that binds to a specific molecule with high affinity, meaning it will not bind to others. The molecule is added to a mixture of hundreds of trillions of random DNA sequences and explored through a process called bio-panning, reminiscent of sifting river sediment in search of gold. This method has been shown to be effective at levels of 30 nanograms per milliliter, which is 1000 times better than previous results.

IS GRAPHENE SAFE FOR HUMANS?

The impressive flexibility, exceptional strength, and conductive properties of graphene mean it has potential in many areas from water filtration to making supercomputers and medical devices. And the first preliminary clinical trial by the University of Edinburgh suggests that our respiratory system can tolerate at least short-term exposure to low concentrations of graphene nanoparticles.

Research published in the journal Nature Nanotechnology showed that volunteers did not experience clear changes in their respiratory or cardiovascular systems, nor did they show signs of inflammation after inhaling very pure graphene oxide. However, researchers did notice a slight increase in blood clotting when testing graphene on a model of an injured artery outside the human body. This means that tiny nanoparticles, thousands of times thinner than our hair, may not be entirely pure, so research continues to determine the safety limits of graphene

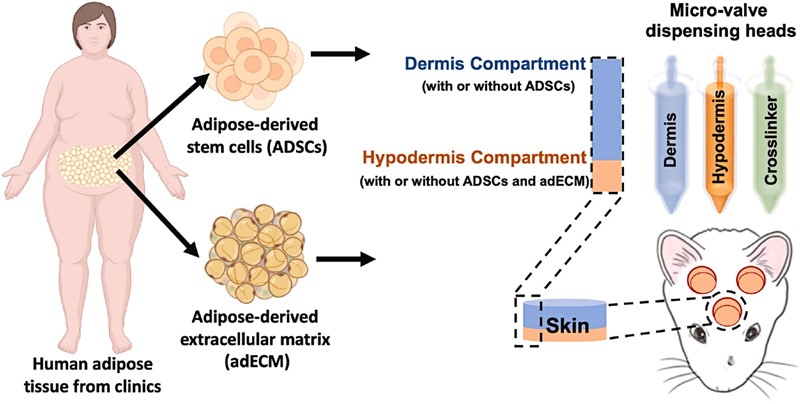

3D BIOPRINTING FOR NEW SKIN

Reconstructive surgery of the face or head is not perfect and usually leaves permanent scars or permanent hair loss. This could soon change as researchers from Penn State University managed to apply layers of skin over a wound during surgery using 3D bioprinting to accelerate the healing process of damaged skin.

During the procedure described in the journal Bioactive Materials, researchers led by Associate Professor of Surgery Dino Ravnic used ink derived from adipose tissue, stem cells, and a clotting solution to help the components bind and form tissue at the injured site. After the operation, the hypodermis contained hair follicles in the early stage and took on a role in regulating and maintaining fat cells. Further research, they say, could help hair grow back after trauma.

ROBOTS AND CAMERAS MADE OF LIQUID CRYSTALS

Thanks to a discovery that significantly expands the potential of chemicals common in computer screens and digital watches, robots and cameras could soon be made from liquid crystals. This simple and inexpensive way of manipulating the molecular properties of liquid crystals by exposing them to light is described in Advanced Materials.

The findings of physicists at Johns Hopkins University could spur the development of programmable tools that change shape in response to stimuli, such as those resembling rubber in soft robots or camera lenses that automatically focus depending on lighting conditions. Scientists now want to patent their discovery and plan to further test it with different types of liquid crystal molecules and solidified polymers made from these molecules.